Conversion and recovery of energy and useful materials from waste

valuation of energy and useful compounds from organic waste and sludge

With our ‘venus’ technology, we bring together all our process expertise, application knowledge, and experience in development of standardized reliable sytems in the niche of ‘conversion and recovery of energy and useful materials from waste’. We take it as our challenge to create and promote economically viable and ecologically sound “local” solutions to dry, recover useful compounds and produce energy from specific waste and sludge streams. It is our ultimate goal to spread the use, and to uncover the immense potential of this long hidden novel Unecco process technology, and to lower scale barriers for ecological and sustainable local solutions with the smallest total carbon footprint and environmental impact.

Whether it concerns industrial waste water treatment sludge, rendering or catering waste, oil drilling waste sludge, used big rubber tires, e-waste, pharmaceutical or pesticide waste and stocks, vegetal oil waste or other specific organic waste and sludge : local elimination, conversion and energy extraction is the way to go for us.

VVnet will primarily be involved in:

- Supporting product development, market penetration, branding, sales, service and exploitation of proprietary and shared ecological products and solutions

- Guiding or advising research and competence centers or platforms for specific, novel and promising advantages of the Unecco® process technology in different fields

- Engaging with professional partners - through licensing or otherwise - to help develop B(O)O(T) activities and business in specific area’s or markets, based on this unique technology

- Setting up local representation centers, combined with an exploitation activity, in selected countries to spread our technologies and products palette in appropriate ways.

Next to offering and developing proprietary and advanced ‘venus’ products and solutions for specific applications, our first focus is to find the right partners to set up full and self supporting technology trade and representation centres, from our headquarters in Belgium, in Singapore, the US and Turkey.

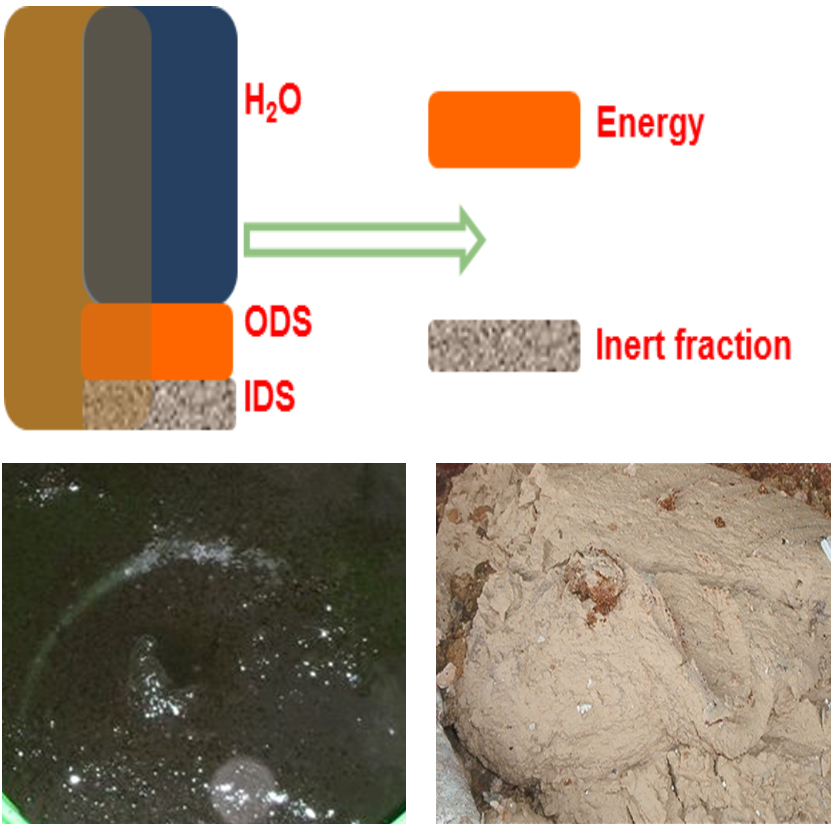

Our VENUS technology is developed to locally (on-site) thoroughly dry and convert ‘difficult’ waste, with relatively high energy content in an ecological way to its dry inorganic base compounds and energy. The dry inorganic compounds can be processed further for different ways of recycling, and the contained energy is primarily made available for sustaining the process itself, while any excess energy can be used as a heat source, and optionally to produce electrical power.

Summary

The internal powerful reactor in our ‘GHIBLI’ systems uses the Unecco® conversion technology, a quite universal and unique complex physicochemical and catalytic conversion process. When introducing waste or sludge in the reactor, the contained water fully (flash-) evaporates, inorganic inserts or compounds are returned to their dry, clean and inert state, and the energy contained in the organic fraction is mainly used directly as a heat source for the process.

The underlying physical process mildly operates between typically 400 and 550 °C without melting or sintering phenomena. It functions without supervision, is proven and reliable, versatile with respect to operating time and conditions, and capable to accept large variations in input flow or composition.

The potential of the VENUS technology lies in this flexibility, its particular benefits for waste streams that are sludgy or contain metals or glass, and the fact that the beating heart of the technology is particularly well conceived to remain simple in operation, can be built modularly and even semi-movable, and is accessible and affordable for local, on-site solutions, even on a ‘limited’ scale.

VVnet strongly believes in eliminating and converting (specialty) waste stream locally, where they are generated, convert them to (re-useable or recyclable) compounds only, with direct local re-use of any excess energy where possible or appropriate. We are convinced that this concept will strongly gain field because of its ecological and carbon footprint advantages.

As a small, specialized and experienced entity, VVnet focuses on the technology, and offers access to the technology to its partners at attractive and supportive conditions, to allow them to integrate and build on this technology and concept. In this way they can realize their own business plans and help spreading the use of this unique technology at the same time.

Typical applications for which our solutions and technology is particularly suited:

- Sludge from industrial waste water treatment plants, on-site plans or plants in industrial estates

- Sludge from municipal waste water treatment plants

- Sludge and waste from oil refining or oil drilling activities, carbon soot, tar waste, tank bottoms

- Waste and sludge from oil industry, including bleaching earth

- Sludge or waste from rendering activities, including meat and bone meal or fish-oil waste

- Cyanide sludge, paint & phosphate sludge or other organic or hydrocarbon waste or sludge

- Waste from catering activities and public transportation services, medical services, …

- Brewery or paper-mill sludge and waste

- Pharmaceutical or pesticide (overdue) stocks that need to be eliminated or destroyed.

- Shredded waste from solar panels, e-waste

- Metal containing waste from (big) tire recycling

- Track recycling rubber removal (Defense)

‘GHIBLI’ suspended particle reactor

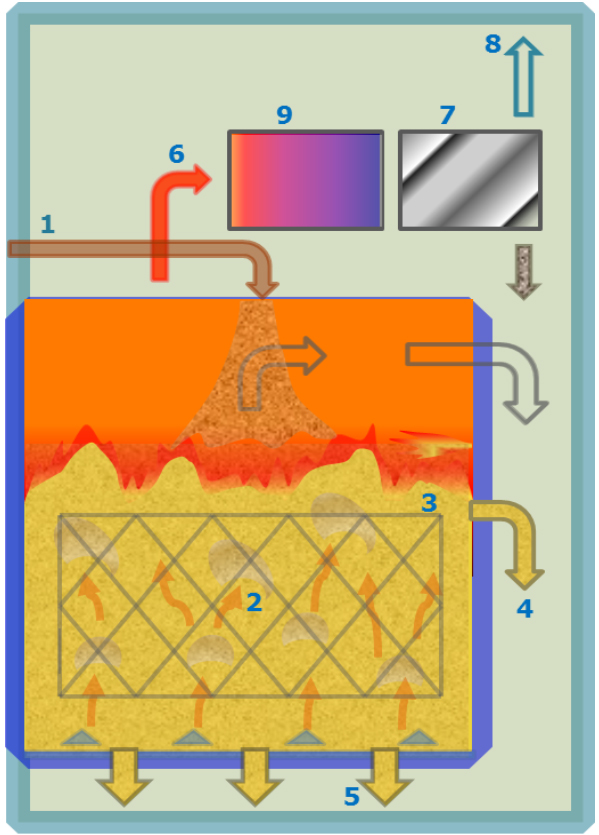

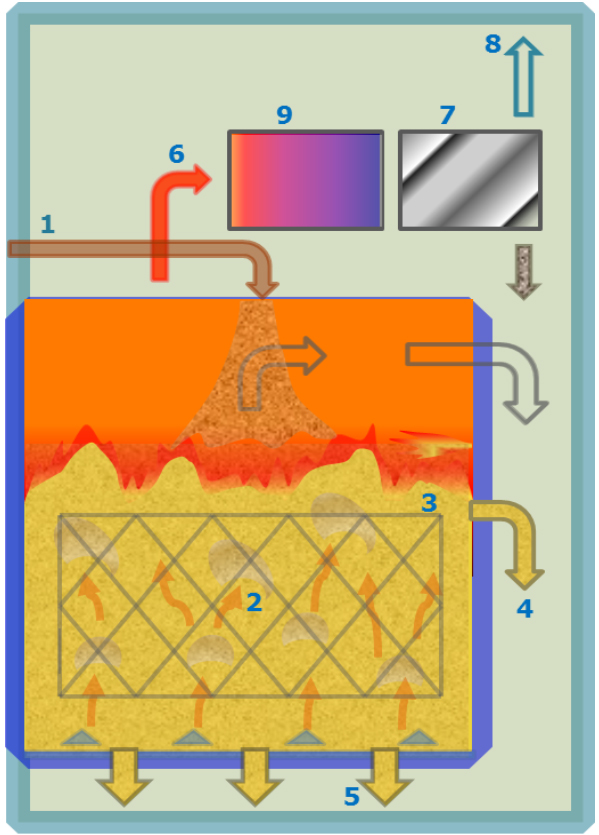

As soon as the system has reached normal operating temperature, the waste or sludge (1) can be introduced or sprayed into the suspended particle reactor based on the powerful Unecco® process, looking and behaving as a boiling liquid. The waste decompose very quickly and will essentially and quickly convert to evaporated water, gaseous or solid organics, and inorganic inserts or fine powder in the bubbling reactor (2).

Depending on the composition and characteristics of the waste, heavier or larger inorganic compounds can either be extracted by means of a collection basket (3), or can overflow (4) or drain (5) to be sieved or separated, or can be carried as fine powder with the flow through the reactor (6) to be separated in a dust collector (7) which can be a cyclone or a barrier filter, before the cleaned exhaust flow is released into atmosphere (8).

The organic fraction transfers part of its energy content directly to the process itself, at low temperature, in the reactor. Before entering the dust separation end phase, the flow from the reactor (6) can go through a multistage gas cleaning phase, possibly with recovery of excess heat (9), and with or without a hot and dry sorption stage to neutralise acid gases. Excess energy which can be used locally or transformed in electrical power depending on scale and needs.

Did you find what you need?

If not, feel free to contact us through phone or email, and we'll answer your questions to the best of our abilities.

About VVnet

Mission

VVnet focuses on technology, product and business development for ecological niche applications, mainly in the field of decontamination, waste or sludge conversion, aluminum treatment and gas cleaning. We are committed to develop and spread promising ‘Novel Ecological Technologies’ with an open approach, through partnership, joint-venture, license or franchise business models, create proprietary ‘niche’ technologies and develop exploitation technologies or products with strategic partners.

Company

VVnet is created to incorporate and centralize ecology- and environment related activities, knowledge and titles from its founders or partners to exploit them in the broadest sense and to market and sell products, services and rights, directly or through participations and partnerships. Our VVnet ‘green valley’ concept lays down our intentions and expresses the green, ethic and sustainable character of all our initiatives : “Pure, simple, natural and clear”, as our mission.