- Call us: +32(0)491/751.552

- vvnet@vvnet.org

short cycle heat treatment and de-coring equipment for aluminium alloy castings

Our ‘scala’ technology has originally been developed in close collaboration with research institutions and industries specialized in green sand aluminum casting technology and rapid prototyping. It has been developed with the intent to play a role in improving the durability of castings and reducing the ecological impact compared to more traditional treatment methods with mechanical shaking stages for de-coring and mould sand removal and huge furnaces and quench tanks for turning a green sand casting from the fresh casting into a finished part ready to be mounted in its final destination.

VVnet can design and supply a well balanced range of all integrated casting heat treatment solutions that can either be supplied as standardized products or can be modified in customized well fitting turn-key systems. We especially offer our expertise to develop validated processes for end users, equipment suppliers or associations, and so wish to contribute to a more ecological world by spreading these modern techniques.

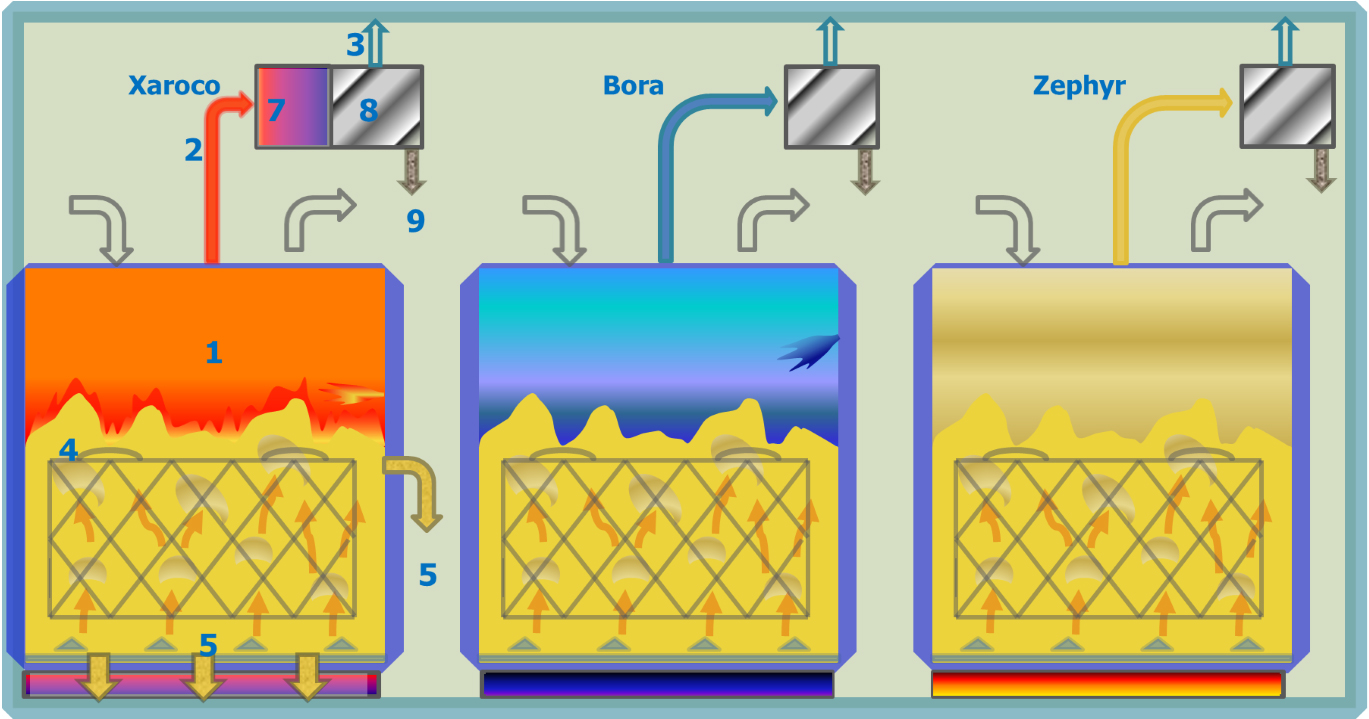

The castings are submerged in the ‘Xaroco’ solution heating and sand removal reactor (1) by means of a carrier (4). The resin from the sand will essentially convert to gas and fine inorganic powder very quickly. Gas and inorganic powder are carried with the flow through the reactor (2), and led into a dust separation device, which can be a cyclone or a barrier filter (8). The inorganic powder is (9) is collected and can be removed daily, and the cleaned exhaust flow (3) is released into atmosphere. As energy recovery can become economic for larger and round the clock operating processes, the flow through the reactor can pass through an energy recovery unit (7) and the generated heat can be used externally or reused for the process itself (6). While the casting is in the solution heating phase, core and mould sand is regenerated, becomes reusable and can be extracted from the unit by draining or overflow (5).

The ‘Xaroco’ reactor can be used stand alone for mould and core sand removal and / or solution heating, can be combined with a ‘Bora’ soft quench reactor with cooled flow or evaporative heat removal device, and with a preheated ‘Zephyr’ reactor in which the ageing process can be ran at very precise temperature.

With this ‘scala’ technology, an all-integrated suspended particle treatment line can process castings with short cycles which are only a fraction of some traditional treatment methods, enhancing quality of the parts and dramatically reducing the carbon footprint of aluminum casting treatment processes.

If not, feel free to contact us through phone or email, and we'll answer your questions to the best of our abilities.

VVnet focuses on technology, product and business development for ecological niche applications, mainly in the field of decontamination, waste or sludge conversion, aluminum treatment and gas cleaning. We are committed to develop and spread promising ‘Novel Ecological Technologies’ with an open approach, through partnership, joint-venture, license or franchise business models, create proprietary ‘niche’ technologies and develop exploitation technologies or products with strategic partners.

VVnet is created to incorporate and centralize ecology- and environment related activities, knowledge and titles from its founders or partners to exploit them in the broadest sense and to market and sell products, services and rights, directly or through participations and partnerships. Our VVnet ‘green valley’ concept lays down our intentions and expresses the green, ethic and sustainable character of all our initiatives : “Pure, simple, natural and clear”, as our mission.